E-Max ceramic crown

specialists

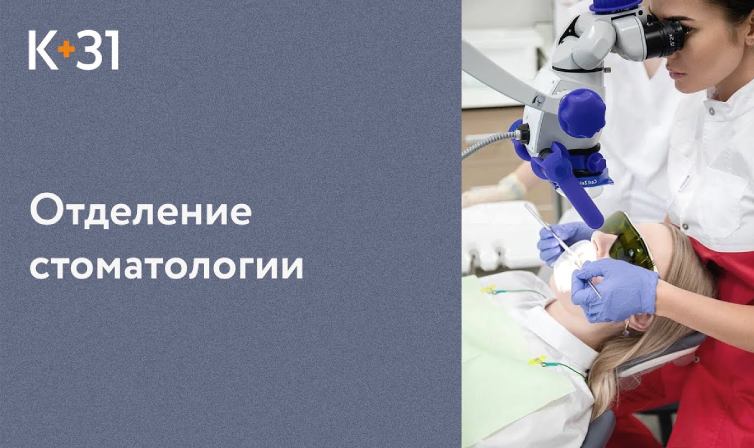

equipment

treatment

Types of orthopedic products made from E-max

Thin ceramic plates - veneers - are used to cover the front teeth. They are especially relevant when:

- Microcracks

- Chipped

- Significant distances between teeth

Inlays are an alternative to traditional fillings: they are intended for the restoration of teeth that are damaged by approximately 30-40%. Such products are usually used in the upper part of the chewing element, after caries has been eliminated.

Crowns and standard fixed dentures help restore teeth damaged by more than 60%.

Characteristics

Emax dental crowns are made of pressed ceramics based on lithium disilicate. Unlike traditional metal-ceramic structures, such prostheses do not contain a metal frame. This allows them to accurately reproduce the shade and transparency of natural enamel.

Dentures can withstand significant chewing loads. This feature allows them to be used even in the lateral parts of the jaw. Despite their strength, E-Max crowns are lightweight. Due to this, significant changes to the supporting teeth are not required when installing the structure.

The surface of the crowns is less susceptible to the formation of plaque and deposits. This helps prevent caries on adjacent teeth.

Advantages of E-Max crowns

Zirconium crowns are made using CAD/CAM computer design technology, converting impressions into digital format. Ceramic crowns are formed using the pressed casting method, which makes them more stable and suitable for the restoration of chewing teeth.

E-max ceramics can be used to make prostheses of various shapes - from lumineers (extremely thin overlays on teeth) and veneers (plates fixed to the outer side of the tooth) to regular crowns and bridges (structures replacing one or more teeth). The main disadvantage of E-max ceramic crowns is their high price.

Ceramic crowns e max have a number of advantages:

- Wear resistance The product can be used without fear of chipping or cracking

- Light weight and minimal thickness The absence of a metal base makes the structure lighter and thinner

- Natural appearance The material is highly transparent and has natural light reflectivity, which allows them to imitate natural teeth as accurately as possible

- Hypoallergenic properties The material does not interact with oral tissues, which eliminates any allergic reactions to the components

- Reliable fixation E-Max is well compatible with adhesive cements, which ensures strong installation

- Minimal tooth preparation Installation requires less grinding of healthy dental tissue, unlike traditional metal structures

General information about the procedure

Answers to popular questions

Dentists from K+31 in Moscow answered the most frequently asked questions about metal-free E-max.

How long do E-max crowns last?

Can E-max crowns cause discomfort?

What to do if sensitivity appears after installing E-max crowns?

Does bruxism affect the durability of E-max crowns?

The opinion of the doctors of the K+31 clinic on problems with inflammation

Modern methods of diagnostics and dental treatment at "K+31"

Our doctors

This award is given to clinics with the highest ratings according to user ratings, a large number of requests from this site, and in the absence of critical violations.

This award is given to clinics with the highest ratings according to user ratings. It means that the place is known, loved, and definitely worth visiting.

The ProDoctors portal collected 500 thousand reviews, compiled a rating of doctors based on them and awarded the best. We are proud that our doctors are among those awarded.

Make an appointment at a convenient time on the nearest date

Price

Other Services

Manufacturing technologies

In the process of creating emax crowns, 2 technologies are used - pressing and 3D milling.

The pressing method begins with wax modeling and taking an impression. The resulting model is sent to a special oven, where the final shape of the prosthesis is formed under the influence of pressure and temperature. Then, depending on the requirements for restoration, additional decoration is carried out (veneering, painting, glazing).

3D milling technology involves the use of CAD/CAM systems. They are essential for precise and automated production. After an intraoral scan of the patient, a computer program generates a 3D projection of the future prosthesis, which is then implemented on a milling machine. This method virtually eliminates errors in production, and the use of high-quality materials allows you to achieve high strength and aesthetic appeal of the product.